A Massachusetts-based developer of products essential in the building of semiconductor chips has announced a preliminary agreement with the U.S. Department of Commerce for up to $75 million in funding from the federal CHIPS and Science Act.

Entegris will put that money toward the construction of a $600 million manufacturing facility in Colorado Springs; it’s a facility company leaders say will help the U.S. semiconductor supply chain rely less on facilities in foreign countries.

The pandemic years led to massive shortages of the critical — and usually foreign-sourced — computer chips. This led to backups in everything from cars to video games to healthcare devices. Elected officials identified that shortage and the risk of repeating it as a danger to national security.

Building chips, however, is not the specialty of Entegris. Rather, the company works on protecting the exacting levels of purity required in developing the ever-smaller silicon chips that operate nearly all of our electronics.

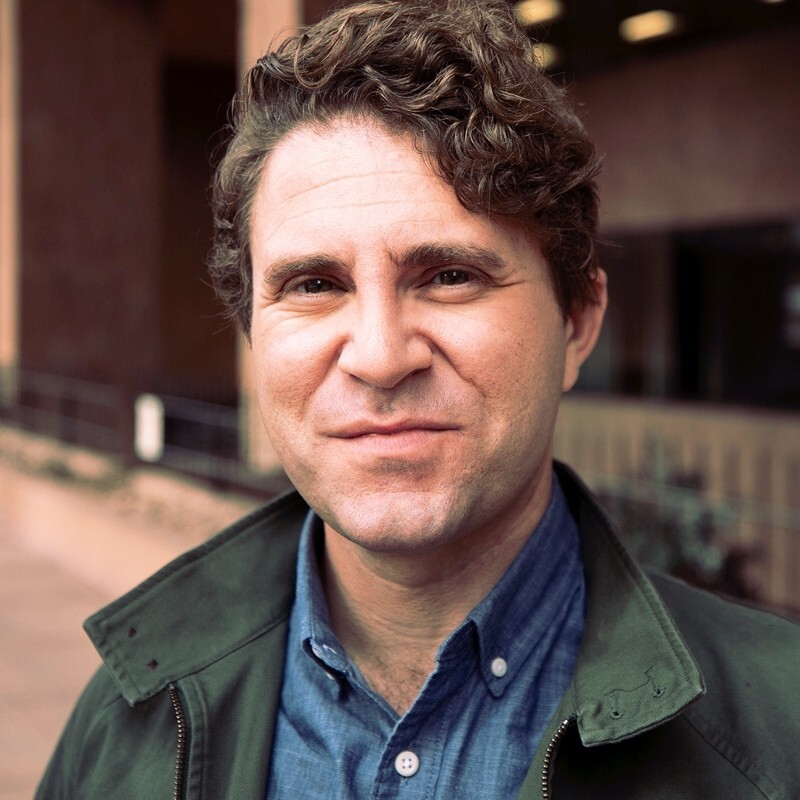

“To make things smaller means that manufacturing processes will be more susceptible to contamination,” Entegris CEO Bertrand Loy said in an interview with CPR News.

Throughout all of the chemical processes used in the production of these chips, precise filtering of contaminants must occur for the chips to function. Loy said modern chips require the removal of contaminants on the atomic level, measured in parts per quadrillion.

“This is equivalent to trying to identify a couple of minnows in the Bay of San Francisco,” Loy said. ”And to remove them selectively while keeping everything else around them intact.”

Along with filtration technologies, Entegris produces containers called “Front-Opening-Unified Pods” (or FOUPs) which protect silicon wafers and maintain their chemical purity as they are transported during the production process.

Bill Shaner, President of the company’s advanced materials handling division, said the technology behind the FOUPs was originally engineered in Colorado. Today, he said 100 percent of these important containers are manufactured in Asia.

That means the Colorado Springs Entegris facility could be critical to helping on-shore production of these FOUPs. The building is already under construction near the city’s Ute Valley Park. The site is expected to begin its commercial operations in 2025, with more phases of construction expected in the future.

A press release on the CHIPS Act grant from the Commerce Department said the facility will create 600 direct manufacturing jobs over the next few years and “approximately 500 construction jobs by 2030.”

“If you think about all of the future, most advanced semiconductor (producers) that will be built in the U.S., or Europe for that matter, they will all be relying on critical products that are all coming from Colorado Springs,” Loy said.

In January, semiconductor producer Microchip announced $90 million in CHIPS Act funds for its Colorado Springs facility. Microchip uses Entegris technologies in its manufacturing processes.